Blog: Build your own Hangglider and Paraglider Winch

Choice of wire

It is recommended not to use cheap chineese wires as:

– Cheap wires are thicker, takes up more volume on the drum, which increases the risk of “wire jam”.

– The lifetime is better with quality wire.

– It is easy to spice, you can use a piece of welding wire a slicing tool.

– Requires more power from the sled stepper motor

– Generates more drag in the air, which means less altitude

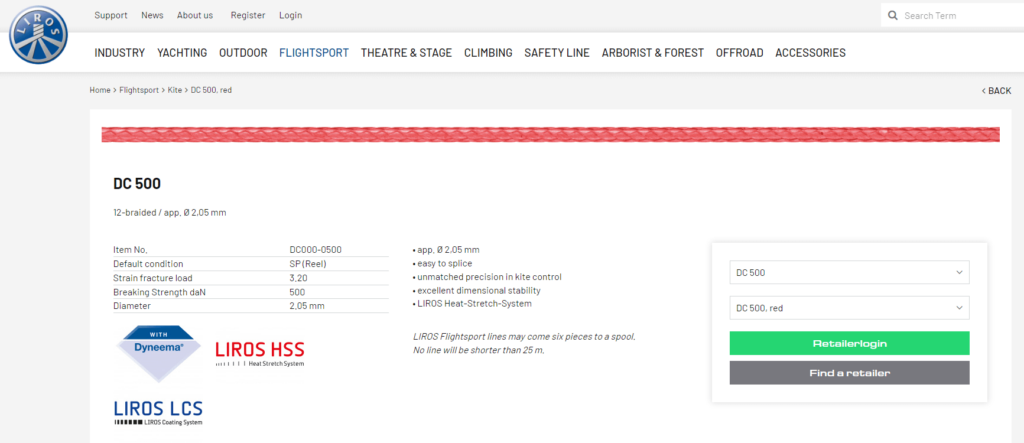

Use Liros DC500.

It is a quality wire, which costs around 500-600€ for 1000m.

We have also tried Liros DC Pro that is only Ø1.6mm, and it is still easy to splice.

Design of wirecutter

The idea behind this construction was to make a wirecutter that could be actuated by an electrical input.

In the end, it became a very effective solution. When the wirecutter is activated the 25mm hobby knife blade will be angled two times 45° to the wire, which will make the wire cut itself by pulling the wire with a force lower than 0.5kg.

The actuator is a 12V solonoid that gets 24V (only few seconds), when the wirecutter is activated.