Blog: Build your own Hangglider and Paraglider Winch

Update 03/04-2025: Addition of a tablet based remote control by using Webvisu and VPN connection.

How it looks when pulling slightly with paraglider students. Note, how steady the Ø2.05 dyneema wire is.

How it looks when retrieving the wire with 60km/h, which is the normal retrieving speed.

System description

The thoughts behind the design, was to make a winch with optimal performance, flexible design, with minimum mechanical complexity and build by simple and cheap techniqes that everyone can do with basic tools, and by easy accessible components.

The speed of the drum is up to 3000 rpm, which is an optimal speed of a wide majority of motors.

A servomotor is used to wind up the wire in equal layers on the drum. The synchronization between sled and drum and the overall control of the winch is done by a industrial PLC, this could also be done by any other kind of controller.

The wire cutter is based on a 25mm width hobby knife blade, which is placed in an angle 2 x 45° to the wire.

The main dimensions are based on the drum which is Ø120x1000mm.

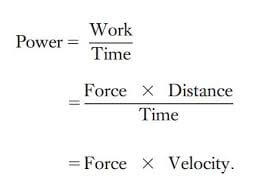

Main specifications and calculations

The most important questions are:

– How much force do you want?

– How much speed do you requirer?

Our expirences is 120kg for a tandem flight and 65km/h as max speed for both hanggliders and paragliders.

On the left side you can see the main specifications of the winch. If you change the numbers, you will see how they affects each other.

Calculations on “Next” page is related to the PLC-program and the programming of the zig-zag pattern.